Agile, Lean, Six Sigma. You’ve heard the terms, maybe even used them in a sentence. But what do they really mean? Are they rivals for the same throne, close allies, or just different buzzwords for the same thing? This guide will give you a clear, straightforward breakdown of each philosophy.

What is Agile?

To answer the question ‘’what is agile?’’, etymology can be super helpful. The word ‘agile’ comes from Latin ‘agere’ which means ‘’to set in motion, keep in movement’’.

So, in its root, agile means continuous progress. It is not a strict rulebook that answers questions like ideal team size or responsibilities of a manager. It is a mindset, it is an answer to changing needs and circumstances.

A Brief History the Agile Manifesto

The Agile movement was born from the “software crisis” of the 1990s, when traditional “waterfall” methods proved too slow and rigid for the fast-paced tech industry. In 2001, a group of 17 software developers met in Snowbird, Utah, to find a better way. The result was the Manifesto for Agile Software Development, which gave this new, adaptive approach its name.

What are the 4 Core Values of the Agile Manifesto?

The Manifesto is built on 4 core values. While the items on the right are important, Agile places a higher value on the items on the left:

- Individuals and interactions over processes and tools

- Working software over comprehensive documentation

- Customer collaboration over contract negotiation

- Responding to change over following a plan

What are the 12 Guiding Principles of Agile?

The Manifesto is supported by 12 guiding principles that help teams put the Agile mindset into practice:

- Our highest priority is to satisfy the customer through early and continuous delivery of valuable software.

- Welcome changing requirements, even late in development. Agile processes harness change for the customer’s competitive advantage.

- Deliver working software frequently, from a couple of weeks to a couple of months, with a preference to the shorter timescale.

- Business people and developers must work together daily throughout the project.

- Build projects around motivated individuals. Give them the environment and support they need, and trust them to get the job done.

- The most efficient and effective method of conveying information to and within a development team is face-to-face conversation.

- Working software is the primary measure of progress.

- Agile processes promote sustainable development. The sponsors, developers, and users should be able to maintain a constant pace indefinitely.

- Continuous attention to technical excellence and good design enhances agility.

- Simplicity–the art of maximizing the amount of work not done–is essential.

- The best architectures, requirements, and designs emerge from self-organizing teams.

- At regular intervals, the team reflects on how to become more effective, then tunes and adjusts its behavior accordingly.

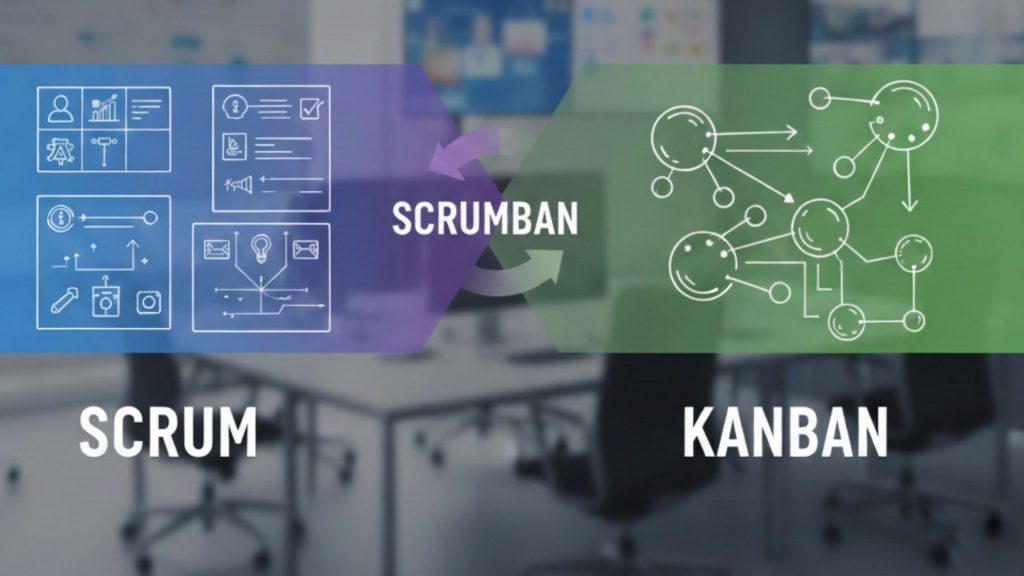

Agile in Action: An Overview of Scrum and Kanban

Lots of questions arise like ‘’Is Agile or Kanban/Scrum better?’’. Well, this is not a correct question.

Scrum and Kanban are not Agile itself; they are popular frameworks that give teams a structure for practicing Agile principles.

Scrum: The Framework of Iteration

Scrum organizes work into fixed-length, iterative cycles called Sprints (typically 1-4 weeks). It uses three key roles (Product Owner, Scrum Master, Development Team), four main events (Sprint Planning, Daily Stand-up, Sprint Review, Sprint Retrospective), and three artifacts (Product Backlog, Sprint Backlog, Increment) to manage complex projects.

Kanban: The Framework of Flow

Kanban is a more flexible framework focused on visualizing work, managing flow, and limiting Work in Progress (WIP). Using a Kanban board, teams pull work as they have capacity, creating a smooth, continuous delivery of value. It relies on key metrics like Lead Time and Cycle Time to measure and improve efficiency.

What are the Advantages & Disadvantages of Agile?

Nothing is perfect. Every single methodology has its unique way to handle things. It is not different when it comes to Agile. Here are main advantages and disadvantages of Agile:

Advantages of Agile

Flexibility: Easily adapts to changing requirements.

Faster Delivery: Incremental releases get value to market sooner.

Customer Satisfaction: Continuous feedback ensures the final product meets customer needs.

Team Morale: Empowered, self-organizing teams have a greater sense of ownership.

Disadvantages of Agile

Difficult Long-Term Planning: The focus on adaptation makes it hard to predict final costs and timelines upfront.

Limited Documentation: The emphasis on working software can lead to a lack of documentation.

Potential for Scope Creep: Without a clear endpoint, the project can expand indefinitely.

Fragmented Output: Incremental delivery can sometimes result in a collection of disconnected features.

What is Lean? Maximizing Value, Minimizing Everything Else

Lean is a philosophy focused on a simple goal: to preserve value with less work. It seeks to deliver perfect value to the customer by creating a process with zero waste. So, in Lean methodology, any kind of activity is considered waste if it doesn’t add value from the ‘customer’s perspective’. And if it doesn’t add value, it has to be eliminated.

Best way to explain Lean methodology is Japanese word ‘kaizen’. It means change for better. This is the core philosophy behind Lean. In Lean, the whole organization is aiming for a continual improvement, and small changes make big difference in the long run.

A Brief History: From the Toyota Factory Floor to Your Kanban Board

Lean originated with the Toyota Production System (TPS) in post-WWII Japan. Developed by pioneers like Taiichi Ohno, TPS was built on two pillars: Jidoka (“automation with a human touch”) to ensure quality, and Just-in-Time (JIT), which dictates making only what is needed, when it is needed. The term “Lean” was coined in the 1991 book The Machine That Changed the World, which introduced the philosophy to a global audience.

What are the 5 Core Principles of Lean Thinking?

Lean Thinking distilled the TPS into 5 core principles that provide a clear roadmap for any organization:

Identify Value: Define value from the customer’s perspective.

Map the Value Stream: Visualize the entire end-to-end process to identify waste.

Create Flow: Eliminate bottlenecks so work moves smoothly and without interruption.

Establish Pull: Initiate work only when there is a signal of demand from the customer.

Seek Perfection: Continuously repeat the cycle to pursue perfection.

What are the 8 Wastes of Lean (DOWNTIME)?

Lean defines waste (muda) as any activity that consumes resources but creates no value for the customer. They are often remembered by the acronym DOWNTIME :

Defects: Work that contains errors, lacks something necessary, or fails to meet quality standards. Overproduction: Producing more of a product or information than is needed by the customer at that moment.

Waiting: Idle time created when people, information, materials, or equipment are not ready.

Non-Utilized Talent: Not using employees’ skills, creativity, and knowledge to their full potential.

Transportation: Unnecessary movement of materials, information, or products that does not add value.

Inventory: Having more materials or products on hand than is currently needed for the process.

Motion: Unnecessary movement of people that does not add value to the product or service.

Extra-Processing: Performing efforts or steps in a process that are not valued by the customer.

What are the Advantages & Disadvantages of Lean?

Advantages of Lean

Increased Efficiency: Streamlines processes and lowers operational costs.

Improved Quality: A focus on customer value and eliminating defects leads to a higher-quality product.

Empowered Teams: The “Respect for People” principle boosts morale and innovation.

Disadvantages of Lean

Requires Strong Discipline: Demands a significant cultural shift and buy-in at all levels.

Low Margin for Error: The Just-in-Time approach leaves little buffer for unexpected disruptions.

Can Stifle Radical Innovation: A rigid focus on optimizing existing processes can sometimes discourage out-of-the-box thinking.

High Team Dependency: Success is highly dependent on a skilled and consistent team.

What is Six Sigma? The Statistical Pursuit of Perfection

Six Sigma is a disciplined, data-driven methodology for quality control. Its primary goal is to reduce defects and minimize variation to a level of near-perfection. A process operating at a Six Sigma level produces no more than 3.4 Defects Per Million Opportunities (DPMO), an accuracy rate of 99.99966%.

A Brief History: Motorola’s Answer to a Quality Crisis

Six Sigma was developed at Motorola in 1986 by engineer Bill Smith to compete with higher-quality products from Japanese manufacturers. It gained global fame in the 1990s when General Electric (GE) CEO Jack Welch adopted it company-wide, leading to billions in cost savings.

What are the Six Sigma Methodologies: DMAIC vs. DMADV?

Six Sigma projects follow one of two structured roadmaps:

DMAIC: Improving the Existing

Used to improve an existing process, DMAIC stands for:

- Define the problem.

- Measure the current process performance.

- Analyze the data to find the root causes of defects.

- Improve the process by implementing solutions.

- Control the new process to ensure improvements are sustained.

DMADV: Designing the New (aka DFSS)

Used to design a new product or process, DMADV (Design for Six Sigma) stands for:

- Define the design goals.

- Measure what is Critical to Quality for the customer.

- Analyze different design alternatives.

- Design the new product or process.

- Verify that the design meets customer needs.

What are the Six Sigma Belts?

Inspired by martial arts, Six Sigma uses a “Belt” system to signify different levels of expertise:

White/Yellow Belts: Have a basic understanding and can participate in projects.

Green Belts: Lead smaller-scale improvement projects.

Black Belts: Highly trained experts who lead critical projects full-time.

Master Black Belts: The highest level of leadership; they train and mentor other Belts.

Champions: Senior managers who sponsor projects and remove organizational barriers.

Advantages & Disadvantages of Six Sigma

Advantages of Six Sigma

Drastic Quality Improvement: Systematically reduces defects and errors.

Data-Driven Decisions: Replaces guesswork with decisions grounded in statistical analysis.

Significant Cost Savings: Delivers a clear, quantifiable return on investment.

Enhanced Customer Satisfaction: Consistently high-quality leads to increased customer loyalty.

Disadvantages of Six Sigma

Complexity and Rigidity: Requires significant investment in training and statistical tools.

Can Stifle Creativity: The intense focus on controlling processes can be at odds with innovation.

High Implementation Cost: Training and certification can be a significant upfront investment.

Overemphasis on Metrics: There is a risk of focusing more on certifications than on genuine business impact.

How to Build Your Own System for Continuous Improvement?

Instead of viewing Agile, Lean, and Six Sigma as competing ideologies, it’s better to see them as a powerful toolkit for organizational excellence. Each offers a unique strength: Agile delivers adaptability to navigate uncertainty, Lean provides the blueprint for relentless efficiency, and Six Sigma offers the data-driven discipline to achieve near-perfect quality.

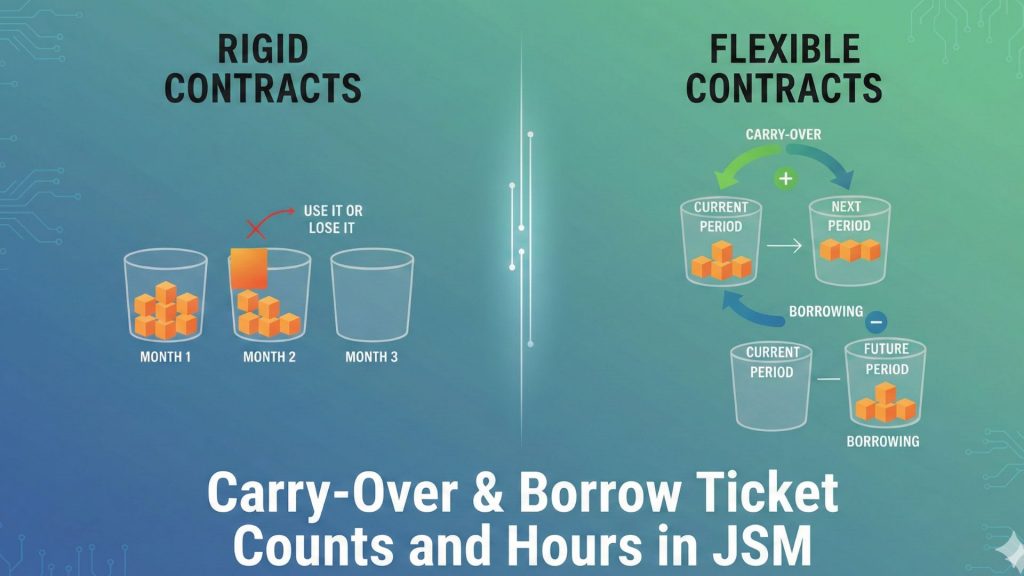

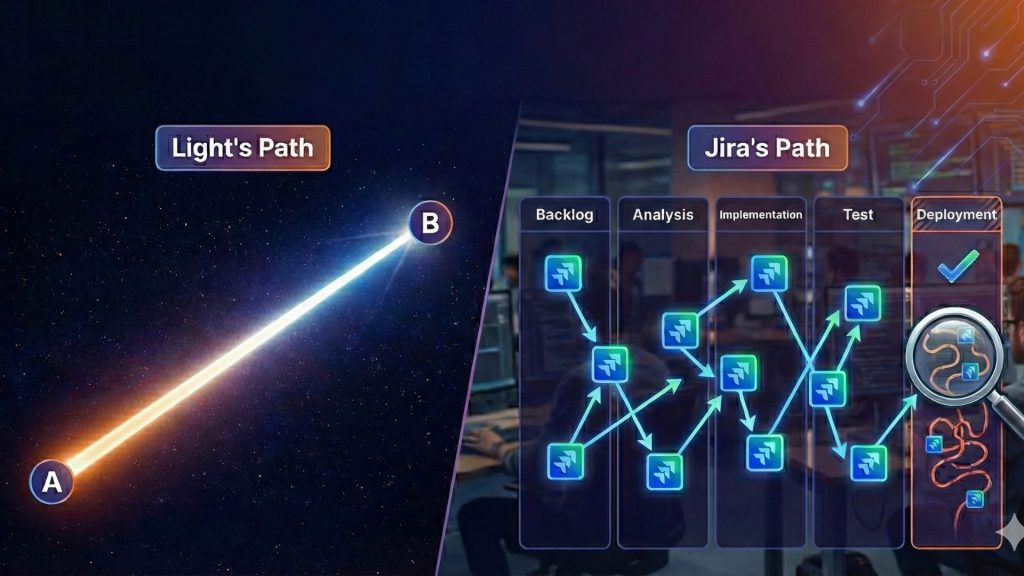

The real question isn’t which one to choose, but how to use any of it strength to get better results. The most successful organizations don’t force themselves into a single methodological box. Instead, they become masters of continuous improvement by borrowing from each philosophy. So, you can use Lean principles to streamline their Agile workflows and apply Six Sigma’s precision to solve the most stubborn bottlenecks. The goal is building a custom system that is perfectly matches the company’s needs.

A flexible platform like the Atlassian ecosystem is the perfect foundation for this hybrid approach. To truly unlock its potential, you need tools that enhance your specific framework. To discover how specialized apps can sharpen your implementation and accelerate your journey toward operational excellence, explore the offerings from OBSS Apps on the Atlassian Marketplace.